9-18-16 update Mar 2018

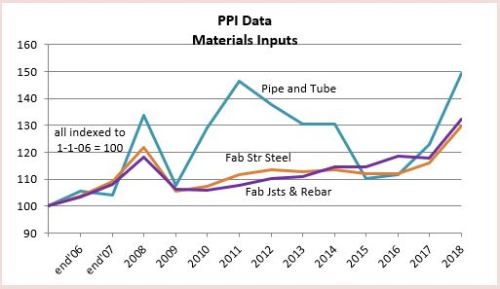

Recent articles suggest that steel cost is expected to increase and this will almost certainly affect the cost of construction. But just how much of an affect would a cost increase have on total building cost? The cost increase that is being talked about is the mill price cost of steel, or something like pipe and tube producer price (PPI), since pipe and tube is a world trade item, but not a Fab Steel PPI. None of these include total cost of steel installed. The PPI is the price after fabrication. Total cost is the contractor’s bid or selling price installed which includes all markups (or markdowns).

PPI Steel Materials Inputs plot updated 2-10-19 to include 2018 data

The questions we need to answer are:

- How much of a cost increase will we see in the raw product, manufactured raw steel?

- How much steel is used in a building?

- What affect will a raw material cost increase have on the cost of steel installed?

- How much does that change the cost of the building?

It might help to start with a basic understanding of steel manufacturing and use.

Basic Oxygen Steel (BOS) steel making uses between 25 and 35% recycled steel to make new steel. BOS steel usually has less residual elements in it, such as copper, nickel and molybdenum and is therefore more malleable than EAF steel so it is often used to make automotive bodies, food cans, industrial drums or any product with a large degree of cold working. Cold rolled steel is in this category which would include gypsum wall system steel studs and HSS Hollow Structural Sections.

Electric Arc Furnace (EAF) steel making contains more residual elements that cannot be removed through the application of oxygen and lime. It is used to make structural beams, plates, reinforcing bar and other products that require little cold working. EAF steel uses almost 100% recycled steel. Most steel that goes into a building or civil structure is in this category. 2/3rds of all steel manufactured in the US is EAF steel.

Typically quoted benchmark steel pricing that I’ve seen is based on either cold-rolled-coil sheet steel or hot-rolled-coil sheet steel. This is a common product used for the automotive industry or appliance, but not so much for the construction industry (steel studs vs structural steel). EAF Structural steel is nearly 100% dependent on recycled steel so is not as much affected by price changes of iron ore, as is BOS steel.

The United States is the world’s largest steel importer. Of the 30MMT imported, 50%+ of that comes from our top few import suppliers, Canada, Brazil, South Korea and Mexico. Russia supplies 7%-9%. No other country supplies more than 5% of our imports. China supplies less than 2% of our steel imports, The U.S. is responsible for almost 10% of global steel imports, more than double the second largest importer. The U.S. annually imports about $20-$25 billion of steel, $2 billion from Mexico.

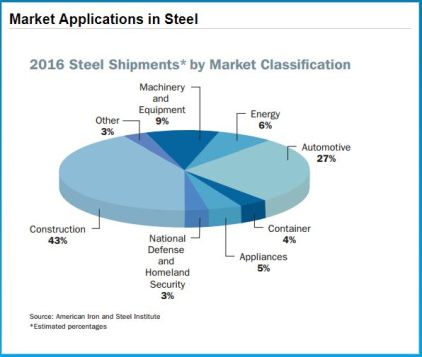

The United States consumes approximately 110 million tons of steel each year. More than 40 million tons is used in the construction industry. The next largest industries, automotive and equipment and machinery, together do not use as much steel as construction. The U.S. imports about 30% of the steel it uses.

The graphic chart above is by American Iron and Steel Institute.

Structural steel is the most widely used structural framing material for buildings used in the U.S. with nearly 50% market share in nonresidential and multistory residential buildings. Prior to the recession steel had a 60% market share.

Sources are also linked below.

What affect might a steel cost increase have on a building project? It will affect the cost of structural shapes, steel joists, reinforcing steel, metal deck, stairs and rails, metal panels, metal ceilings, wall studs, door frames, canopies, steel duct, steel pipe and conduit. Structural steel and reinforcing steel are hot-rolled long products, EAF steel. All the others are cold-rolled flat sheet BOS steel.

Here are some averages of the percentage of steel material costs as related to total project construction cost. For a building that is predominantly masonry, these percentages would be reduced considerably. For a heavy industrial building the percentages might be higher.

Assuming a typical structural steel building with some metal panel exterior, steel pan stairs, metal deck floors, steel doors and frames and steel studs in walls, then all steel material installed represents about 14% to 16% of total building cost.

Structural Steel only, installed, is about 9% to 10% of total building cost, but applies to only 60% market share of steel buildings. The other 6% of total building cost applies to all buildings.

Other steel is very likely higher to take into account any increased cost in major mechanical equipment such as chillers, pumps, fan powered boxes, cooling towers, tanks, generators, plumbing fixture supports, electrical panel boxes and cable trays.

If the structural steel subcontractor increases bid price by 10%, that raises the cost of the building by 1%, but if it is the mill price of steel that increases by 10% the increase to final building price is far less. It is the mill price of steel, rather than fabricated steel, that you would track in the producer price index (PPI).

The final cost of steel installed in a building is about four times the cost of the raw mill steel material used in making and installing the final product. Why so different? Well, for instance, structural steel cost includes: raw mill steel cost, delivery to shop, drafting, shop fabrication, shop paint, delivery to job site and shop markup. At the job site it includes: unload and sort, field installation crew, welding machine, crane and operator, contractor’s overhead and profit and sales tax.

Assuming a building as described above, a 10% increase in the cost of mill steel, which (material only) affects one fourth the cost of 16% of the total building cost, then a 10% increase in the cost of ALL mill steel may result in a composite price increase on a whole building of about 10% x ¼ x 16% = 0.4%. A 10% increase in the cost of mill steel just for structure may result in a composite price increase on a whole building of about 10% x ¼ x 10% = 0.25%.

So, if the mill cost of steel were to increase 10% from $700/ton to $770/ton prior to shop fabrication, for a $100 million building, that could add roughly 0.25% ($250,000) to the cost of the structural steel contract or roughly 0.4% ($400,000) to the total cost of all steel.

A 25% increase in mill steel could add 0.65% to final cost of building just for structure. It adds 1.0% for all steel in a building.

For a project such as a steel bridge, where not just 16% of cost is steel material, but potentially 40% to 60% of cost is steel, a 25% increase in mill steel might add as much as 3% to 4% to final cost.

links to relevant data

Steel Imports Report Global Steel Trade Monitor

Steel Capacity Utilization and Use American Iron and Steel Institute

Structural Steel Industry Overview AISC

World Steel Production – Consumption – Imports – Exports

Crain’s NY – Impact of steel tariffs already being felt in NYC

Thanks for explaining that BOS steel is made using up to 35% recycled materials. My brother wants to find a ferrous steel recycling service for some of the materials from the commercial demolition project he’s planing. Asking about these types of steel should help him find a knowledgeable recycling service, so I’ll be sure to pass along that advice!

LikeLike

I appreciate how this article clarified that the final cost of steel installed in the building is roughly four times what the raw steel mill material costs. It’s handy to know what your final costs might look like when starting a project. I may share this information with some friends in the industry to help them out in calculating project costs.

LikeLike

That’s interesting that steel is about ten percent of the building costs. I would have thought that it would make up a lot more than that since a building would be mostly made of steel. It must be a lot cheaper than a lot of the other stuff that goes into a building.

LikeLike

Thank you for writing this awesome article. I’m a long time reader but I’ve never been

compelled to leave a comment.

LikeLiked by 1 person

I actually had no idea structural steel is a hot-rolled product, while most others are cold-rolled. To be honest, I’m a bit interested in learning more about the processes of making these types of products. It could be interesting to learn a bit more about how they are different as well as the many applications of them.

LikeLike

Hi Taylor. Thanks for the comment. Details of steel manufacturing processes are a bit beyond the scope of this blog. However, there are volumes of information to be found on the web. edz

LikeLike

Hi Ed – interesting discussion. I’d be interested to know how much of a raise in steel mill cost actually translates to the installed cost – competition between suppliers can put a limit on the amount the supplier can charge for its input price changes.

LikeLike

It m ight be impossible to determine this since competition is not a published value. In some cases though it might be zero.

LikeLike